Needs and Contact

Needs and Contact

Contact us

Contact us

Since Dongfang Precision Group acquired the Fosber Group in 2014, it has actively achieved integration with the acquired companies and produced great results. In recent years, the Dongfang Precision Group has been growing at a rapid rate, through acquisition as well as increasing market share in its various fields of operation.

While promoting the collaboration and integration of business entities, we wanted to find out how Dongfang Precision looks to secure operational efficiency and sustainable development. Recently, we talked with Tang Zhuolin, Chairman of Dongfang Precision Group, who shed some light on the future strategic outlook of Dongfang Precision.

IPBI:Dongfang Precision has been established for more than 20 years. It has grown step by step from Foshan in China to a global provider. In this process, how did you recruit and make good use of the talents?

TZ:In the early stage of development as a privately owned business, we did have a certain degree of difficulty in attracting talents, because the paper packaging industry is not as attractive as some other industries such as the IT industry. So, we mainly developed through school recruitment and internal training, and our employees grew with us in the initial stages. In terms of R&D, I was the chief engineer until 2014, but of course I am still inspired by innovation for R&D. Because of this pursuit of high quality, we try to ensure we only manufacture innovative and best quality machines.

As the company grew and expanded into international markets, our recruitment of talents still focused on the same values; mutual respect, trust, openness, sharing of multiple cultures, and seeking like-minded talent to grow together.

IPBI:With the continuous expansion of your global footprint, yet under the current COVID- 19 restrictions and the rapidly changing international market environment, how does Dongfang Precision Group coordinate quality, brand and service, so that the group can achieve sustainable and healthy development?

TZ:It certainly takes time to settle the company's quality and brand. At present, the United States is our second largest market and Europe is our third largest market. For example, we have more than 120 installations of flexo converting machines in the US.

As a professional equipment manufacturer, we always adhere to the spirit of craftsmanship. We have been pursuing quality for decades. Our products and service have always been synonymous with high quality; whether in developed or emerging regions, a customer can rest assured that buying our equipment is a solid decision. They can focus on their operation and management without worrying about quality issues and maintenance services.

From the outset of Dongfang, no matter how difficult or complicated the situation is, we have never lowered product quality and service commitment. From the perspective of the stock market, Dongfang Precision's products rank first in the Asia- Pacific region in terms of stock, which has accumulated a good reputation in the industry and is sustainable for the future. It is the quality of excellence and the promise of continuous surpassing that have contributed to the position of the Dongfang Precision brand in the industry.

IPBI:You have grown from humble beginnings and now are one of the larger suppliers of equipment to the global corrugated industry. How do you plan to continue improving in terms of R&D, service and customer experience?

△Headquarter of Dongfang Precision Group in Foshan

△Cloud Installation of Industry 4.0 Technology

TZ:When Dongfang Precision was founded, we only made printing equipment. After being listed in 2011, we have successively integrated Fosber, Tiruna, and Agnati into our group; the equipment produced by these companies has a high degree of market recognition. The experience of the past few decades tells us that with the continuous development of the company, continuous creation of value for customers is the source of common development for all involved. Especially now, with the development of new technologies, how to use them to help customers to upgrade, improve quality, produce and operate more efficiently has always been our key focus.

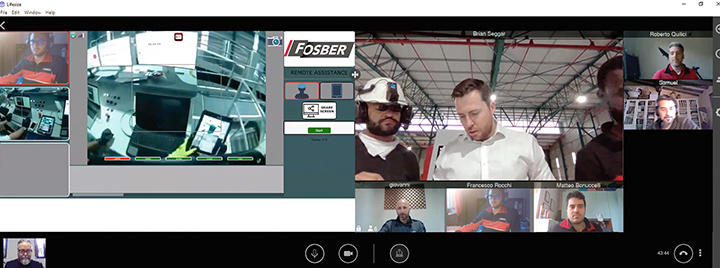

We are now using the ‘Cloud Installation’ with Industry 4.0 technology in customer service, and the first trial installation program using Industry 4.0 technology is located in Fujian, China. For example, at the end of February, when the COVID- 19 situation was starting to ease in China, Fosber was able to deliver equipment and helped customers start up equipment remotely. We started up a complete S/Line with a customer in South Africa, handled by teams from China and Italy remotely. It has been a great way to test new ways of working remotely.

In terms of customer experience, the digital communication module we have combined with AR visual recognition technology has been well received. The four-in-one Industry 4.0 technology of intelligent identification, intelligent diagnosis, intelligent correction and self-learning can detect machine operating conditions online in real time, warn of machine failures and provide correction schemes to ensure the safe, efficient and stable operation of each machine. Our self-developed production management system and other software tailored for customers, with its high degree of automation, is suitable for all machines, and can automatically set production orders for all order specifications and parameters without manual calculations , as well as fast changeover and generate reports automatically to help customers break through capacity bottlenecks.

With the high efficiency, stability and high intelligence, the Smart Corrugator Line manufactured by Fosber, the FFG manufactured by Dongfang Precision and the robots manufactured by Jiateng have greatly reduced the dependence on people, improved the flexibility and adaptability of production and has helped to change the existing model of the corrugated packaging industry that traditionally relied on manpower. We can help customers expand their scale, increase efficiency and production to develop and further enhance their competitive advantages and industry structure.

IPBI:China's packaging industry is small and fragmented and its concentration is not as high as that of the European and American markets. In your opinion, what are some of the future trends of China's packaging industry?

TZ:Affected by the low entry barriers and limited service radius of the corrugated packaging industry, China’s industry has a scatteredproduction capacity and extremely low market concentration. The top five companies have a market share of less than 10%, which is in stark contrast to Europe and America, so there is still much room for improvement in concentration.

With the tightening of China’s environmental protection policies, rising labour costs, the development of e-commerce and the continuous improvement of the automation level of converters, packaging customers have put forward higher and higher requirements for the quality, delivery speed, and cost-effectiveness of corrugated packaging.

As far as the industry is concerned, the corrugator plant and sheet plant with weak management capabilities and poor profits will be quickly replaced and their market share will be gradually replaced by leading companies in the industry. Increasing concentration will be an inevitable trend. Judging from the actual market situation in recent years, industry concentration is accelerating. Data from the National Bureau of Statistics has further verified this point. The number of enterprises above a certain size in the packaging industry has decreased by more than 300 within five years, and the trend of industry consolidation is obvious.

Due to the high efficiency, high quality, cost reduction, environmental protection and energy saving, convenient management, the demand of large packaging groups for fully automatic factories is growing rapidly, which puts forward higher requirements for the automation and information within the plant. At present, there is no overall solution provider for intelligent packaging enterprises in the market, and we rely on our understanding of the industry gathered over many years to provide complete factory solutions for large corrugated groups.

This will also promote the upgrading of industry technology and equipment and accelerate the integration of downstream processes. This trend will apply to the corrugator and converting equipment, further accelerating the increase of equipment concentration, and eliminate equipment manufacturers with low technical content and low production efficiency.

We want to continue evolving into one of the world's leading providers of integrated solutions for intelligent packaging equipment and highend core components and at the same time, help lead the industry in the layout of intelligent plants for packaging production.

IPBI:To continue growth, you need a diverse portfolio. How is Dongfang Precision addressing this to ensure growth in the future?

TZ:Being at the forefront of the industry and seizing opportunities is the foundation of our continuous development over the years. We carried out a global market layout earlier and went out one step ahead of time. We have balanced R&D, production and service centers in Asia, North America and Europe, which can be closer to our customers and respond to complex and volatile political and economic situation steadily. In order to meet the needs of different customers, we not only have high-end products, but also mid-level products, as well as costeffective options. We can use a vast product portfolio to meet the needs of customers in various regions.

The layout of the entire industrial chain of smart packaging has further enhanced our core competitiveness in the market. Whether it is a corrugator, a printing machine, or peripheral equipment, our products are at the forefront of the industry in terms of automation and intelligence and the equipment itself has a high degree of data information processing. From highend corrugators to flexo converting lines, we can offer any solution.

△Overall solution for smart packaging system