Needs and Contact

Needs and Contact

Contact us

Contact us

IPBI:The Smart Packaging Equipment Business in the High-end Intelligent Equipment section of Dongfang Precision has completed the entire industry chain layout and created the world's leading Smart Packaging System Total Solution. Can you introduce us to the Smart Packaging System Total Solution?

Dongfang Precision is one of the global leaders in the field of intelligent corrugated box packaging equipment. It has a full industry chain layout within the industry and has the ability to provide high-end intelligent corrugated box packaging equipment solutions. Dongfang Precision undertakes corrugator line and unit equipment business through its subsidiaries Fosber Group, Fosber Asia, Fosber USA and Italy QCorr.It also undertakes corrugated box printing production line business through Dongfang Precision (China) and Dongfang Precision (Europe),as well as laying out an automated logistics system business through its joint stock company JATEN Robot.

Intelligent factory is a factory with the main characteristics of intelligent design, intelligent production, intelligent management, intelligent logistics and integrated optimization on the basis of digitalization, supported by industrial big data and Internet. In traditional industrial production, production efficiency and the quality of finished products are restricted by many factors, such as manpower, skills, and proficiency. In order to promote the manufacturing accuracy, reliability, consistency and production efficiency to a new height to meet the upgrading production needs, the transformation to automation, digitization and intelligence has become the consensus of the manufacturing industry and gradually accelerate the implementation.

For the printing and packaging industry, intelligent factory is a system engineering with digitalization and intelligence as the core and hardware and software construction as the important content, which represents a leap from traditional automatic production to data interconnection, AI independent learning and decision-making, and flexible production.

IPBI:We know that Fosber Group, a subsidiary of Dongfang Precision, has increased Industry 4.0 and launched the PRO series products. What is the level of Industry 4.0 of Fosber Group?

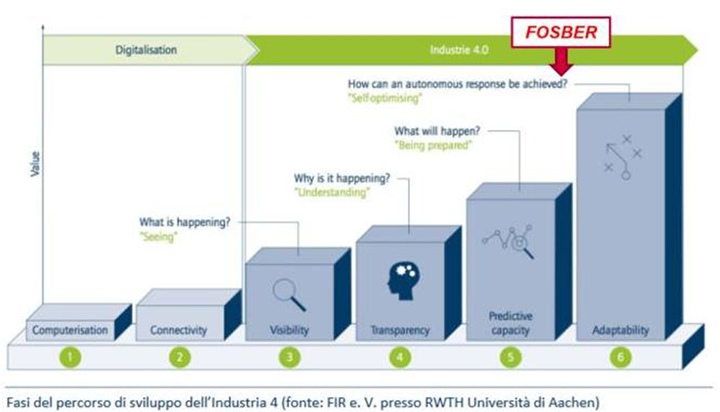

The subsidiary Fosber Group actively implemented the Industry 4.0 model. Industry 4.0 is based on computerization and network connection, and uses big data and algorithms as means to realize the self-learning and intelligent production of machines. The machine's self-learning and intelligent production are divided into four stages: visualization stage (intelligent identification problem), transparency stage (intelligent analysis problem), prediction stage (intelligent prediction problem trend), and adaptive stage (artificial intelligence provides solutions). At present, Fosber has completed the functional design of the above four stages.

Schematic diagram of Fosber Group's stage in the application of Industry 4.0 technology

By combining traditional corrugator liane with advanced artificial intelligence, virtual reality, 3D simulation and other technologies, Fosber Group has developed intelligent systems such as Pro Care and Pro Syncro to realize the operation of the entire production line and individual equipment Intelligent monitoring and control. Based on the application of intelligent manufacturing in the corrugator line, Fosber Group realizes intelligent diagnosis, automatic production planning and management equipment maintenance by automatically analyzing the collected operation data of machine.

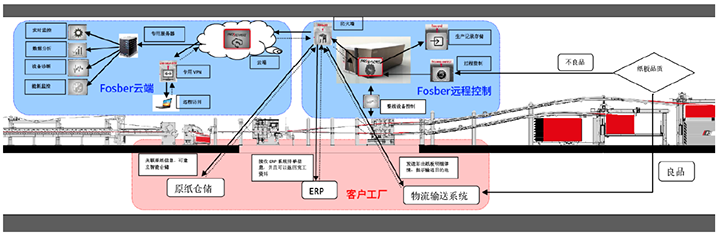

Fosber Group integrates intelligent sensing, AI, VR, 3D modeling technology, and years of accumulated corrugator line development, operation, technical support and other data combined with the development, operation, technical support and other aspects of the PRO series intelligent production management information system,we can dock with customer ERP to achieve ERP scheduling; docking customer warehouse management system to achieve intelligent inventory management and warehousing logistics control.

Through more than 200 sensors installed on the corrugator line, it can realize real-time monitoring of the production data of the corrugator line, real-time monitoring and dashboard management of the production process, and can carry out production line performance analysis and cost analysis based on data to provide support for customer production decisions. According to the real-time collected production data and the setting of the program algorithm, it can identify the abnormal production data in real time, make the automatic diagnosis, and automatically retrieve and output the solution in the database.

The safe storage and transmission of data are realized through dedicated cloud servers and firewalls, and the real-time monitoring and remote control of the equipment are realized through the remote-control system. It can not only effectively reduce the over-dependence on some processes or some personnel in the production process, but also improve production efficiency and ensure the quality of finished products.

Working schematic diagram of PRO series intelligent production management information system of Fosber Group

IPBI:About 50% revenue of Dongfang Precision's printing presses for corrugated packaging comes from overseas markets (mainly the US and European markets). Under the influence of the Covid-19, how is the development of the overseas market for Dongfang Precision's corrugated box printing machine?

Most of the foreign subsidiaries of Dongfang Precision Group are located in Europe. In the first half of 2020, Covid-19 had a certain impact on the shipments and revenues of foreign subsidiaries, mainly due to the slowdown in shipment speed due to logistics restrictions, but the orders in hand of foreign subsidiaries were not significantly affected. For these orders in hand, even if they cannot be included in the revenue in 2020, will be included in 2021. Therefore, I think Covid-19 will affect the overall revenue of the group, but not too much.

At present, Dongfang Precision has three factories in Italy. In the first half of 2020, we are indeed affected by Covid-19 to varying degrees, but production has basically resumed in mid-May. The Fosber Group, a subsidiary of Dongfang Precision, has the second largest market share in the global corrugator line industry. In the first half of 2020, the Fosber Group achieved revenue of approximately 100 million Euros, which was basically the same as the same period last year.

Since 2019, the Fosber Group has successively completed the acquisition of 70% of the shares in the corrugated roll supplier Tiruna Group, and the acquisition of about 60% of the relevant assets of the Italian corrugator line manufacturer Agnati, thus ensuring the suppling of key components of the corrugator line business. We also obtain the business covering the entire value chain of Quantum's high-speed intelligent corrugator line and can provide the world's leading high-speed intelligent corrugator line.

Benefiting from the development of the corrugated packaging industry at home and abroad, the demand for smart corrugated packaging equipment continues to be released. We focus on mainstream customers in Europe, America and China with mid-to-high-end equipment products. In the future, we will continue to deepen the mainstream markets in China, Europe, and North America. At the same time, we will strengthen the development of emerging markets, such as Africa, South Asia and Southeast Asia along the "Belt and Road" countries.

IPBI:Now, the comprehensive strength of Dongfang Precision's high-end intelligent equipment ranks among the top three in the world. What is the future development direction and goal of Dongfang Precision?

The experience of the past few decades tells us that continuous creation of value for customers is the driving force for our mutual development, especially now that new technologies continue to develop, how to use new technologies to help our customers upgrade and be more efficient and more convenient in production and operation has always been our development direction.

The transformation of single manufacturing industry to service intelligent manufacturing industry:

We simultaneously sell the whole machine and the sales of accessories and services, each of which has its own value. The whole machine is a one-time sale with a large single amount; accessories and services can be sold repeatedly in the life cycle of the whole machine, with a higher gross profit margin. The increasing market share of our machine products has led to a rigid increase in the demand for accessories and services. At the same time, high-quality after-sales service in turn promotes the sales of machine products. The two complement each other and achieve mutual success, driving the continuous growth of our overall business. The service revenue of Fosber Group in overseas market has accounted for 30% of the total revenue.

The promotion of digitalization and application:

Recent digital application cases: We use the "Cloud Installation" of Industry 4.0 technology in customer service, and he first trial Installation Program using Industry 4.0 technology is located in Fujian, China. At the end of February when Covid-19 situation was getting better in China and all enterprises struggling to resume opening, Fosber Asia have delivered equipment and start our installation program instantly. The project installs the first high-speed 370m/min corrugator line of Fosber Asia and it is commissioned by teams from China and Italy remotely. To ensure the smooth progress, Fosber Asia decided to make full use of its control system to start the "Cloud Installation" plan, using Industry 4.0 technology to collect and transmit machine data, so that engineers far away in Italy can clearly understand the domestic machine situation, join online with professional knowledge and preform the installation. Due to the covid-19, "Cloud Installation” is also being implemented in other parts of the world , such as South Africa.

Combining software and hardware for common development:

We own Tiruna corrugated roller - Fosber corrugator line - Agnati/Italy QCorr high-end corrugator line - Dongfang Precision automatic Flexo Folder Gluer for corrugated boxand single machine products - Dongfang Precision Europe’s corrugated box printing equipment and automatic pre-press and post-press equipment - Jiateng robot AGV and other products.

We have the most complete and abundant product library of product specifications and market positioning in the industry. For example, in the field of corrugated box printing equipment segment, we can provide up and down printing with a total of 26 different specifications, and different market positioning products, which is far more than competitors and can fully meet the needs of different types of customers.

Dongfang Precision's corrugator line and corrugated box printing machine business have relatively mature practice in the production information management system. The foundation and core of intelligent factory is an intelligent production system composed of ERP, MES, WMS, SCADA, APS and other information systems, in which the production process execution system (MES) is a set of production information management system for production execution. It can provide functions and modules including production process control, manufacturing data management, planning and scheduling management, production scheduling management, inventory management, quality management, cost management, project Kanban management and so on, so as to optimize the production activities from order to product completion in the whole workshop manufacturing process.

The industrial Internet composed of intelligent hardware, Industry 4.0 technology and digital and information software, customer on-site applications all over the world, and big data accumulated in the industry for more than 20 years ,all these helped Dongfang Precision to become an overall solution provider for intelligent packaging systems. It also brings subversive changes to the production methods, business models and competitive landscape of the corrugated packaging industry.